اترك رسالة

Mini Cement Plant, Small Cement Plant 501000TPH EPC Cement Plant

Why a mini cement plant? Mini cement plant is a new cement plant, also known as a small cement plant, which refers to a cement plant with a clinker capacity of 50500tpd Recently, mini cement plant becomes hotter and hotter, what are the advantages of the mini cement plant compared with large or mediumsized cement plants?Cement plants with a clinker capacity below 700tpd can be called mini cement plants or small cement plants Mini cement plants are very popular among small and mediumscale cement manufacturing enterprises since they do not Mini Cement Plant EPC Cement Line Capacity 70 600 TPD

CCG Plant Loesche

The CCG is a smallscale grinding plant designed to produce different types of cement At its heart LOESCHE's wellproven, stateofthe art LM 242 CS vertical roller mill From the feed hoppers, clinker or slag is conveyed to the mill, with the finished product being separated in a highefficiency classifier and collected in the baghouseIn the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Small Scale Cement Plant Mini Cement Production Line

Small Scale Plants in Cement Industry JSTOR

used in most small scale cement plants The number of small cement plants, almost all of them located in rural areas, has increased from about 200 in '1965 to 2,800 in 1973 Total production from the ssmall plant has during the same period increased from roughly 5 million tons to an estimated 20 million tons So, the average size of theSmall Scale Cement Plant,Mini Cement Plant,Hot Sale Cement Machine, Small Scale Cement Plant,Mini Cement Plant,Hot Sale Cement Machine,Cement Plant,Mini Cement Plant,Cement Machine from Supplier or ManufacturerHenan Mining Machinery Co, LtdSmall Scale Cement Plant,Mini Cement Plant,Hot Sale Cement

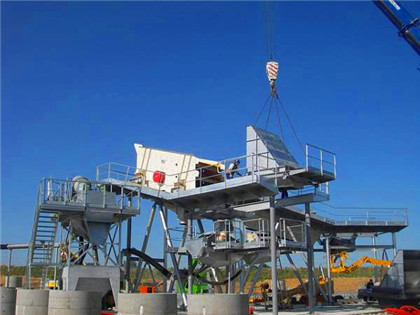

Modular Grinding Plant AGICO Cement Machinery

The modular grinding plant is developed for small/medium but growing markets, especially for markets that only limited cement production capacity, but also a highly flexible system capable of producing a whole range of types of cementSmall Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory, Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory,Grinding Plant,Clinker Grinding Plant,Cement Clinker Grinding Plant from Mine Mill Supplier or ManufacturerHenan Fantianliang Machinery& Equipment Co, LtdSmall Scale Cement Clinker Grinding Plant And Packaging Unit In Cement

Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement

Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory $13,32000 / Set $14,80000 1 Set (Min order) 10% OFF Discount ends in : : : Model Number: LM grinding mill Power: 20 $13,32000 + Samples: 20,LM grinding mill $49,99900 /Set, 1 Set (MOQ): Get samples Trade Assurance protects your Alibaba ordersDr Kache: In August 2020, a highly flexible small scale trial plant (100600kg/h) was commissioned at the R&D facilities of thyssenkrupp’s cement technologies division Ever since, it has been in operation continuously with numerous tests from CEM I, CEM II/A and B cements, to activated clay/LC 3 products, in separate and in cogrindingthe next level in cement grinding? thyssenkrupp Polysius

Mini Cement Plant, Small Cement Plant 501000TPH EPC Cement Plant

Why a mini cement plant? Mini cement plant is a new cement plant, also known as a small cement plant, which refers to a cement plant with a clinker capacity of 50500tpd Recently, mini cement plant becomes hotter and hotter, what are the advantages of the mini cement plant compared with large or mediumsized cement plants?Cement plants with a clinker capacity below 700tpd can be called mini cement plants or small cement plants Mini cement plants are very popular among small and mediumscale cement manufacturing enterprises since they do not Mini Cement Plant EPC Cement Line Capacity 70 600 TPD

CCG Plant Loesche

The CCG is a smallscale grinding plant designed to produce different types of cement At its heart LOESCHE's wellproven, stateofthe art LM 242 CS vertical roller mill From the feed hoppers, clinker or slag is conveyed to the mill, with the finished product being separated in a highefficiency classifier and collected in the baghouseIn the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Small Scale Cement Plant Mini Cement Production Line

Small Scale Plants in Cement Industry JSTOR

used in most small scale cement plants The number of small cement plants, almost all of them located in rural areas, has increased from about 200 in '1965 to 2,800 in 1973 Total production from the ssmall plant has during the same period increased from roughly 5 million tons to an estimated 20 million tons So, the average size of theSmall Scale Cement Plant,Mini Cement Plant,Hot Sale Cement Machine, Small Scale Cement Plant,Mini Cement Plant,Hot Sale Cement Machine,Cement Plant,Mini Cement Plant,Cement Machine from Supplier or ManufacturerHenan Mining Machinery Co, LtdSmall Scale Cement Plant,Mini Cement Plant,Hot Sale Cement

Modular Grinding Plant AGICO Cement Machinery

The modular grinding plant is developed for small/medium but growing markets, especially for markets that only limited cement production capacity, but also a highly flexible system capable of producing a whole range of types of cementSmall Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory, Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory,Grinding Plant,Clinker Grinding Plant,Cement Clinker Grinding Plant from Mine Mill Supplier or ManufacturerHenan Fantianliang Machinery& Equipment Co, LtdSmall Scale Cement Clinker Grinding Plant And Packaging Unit In Cement

Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement

Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory $13,32000 / Set $14,80000 1 Set (Min order) 10% OFF Discount ends in : : : Model Number: LM grinding mill Power: 20 $13,32000 + Samples: 20,LM grinding mill $49,99900 /Set, 1 Set (MOQ): Get samples Trade Assurance protects your Alibaba ordersDr Kache: In August 2020, a highly flexible small scale trial plant (100600kg/h) was commissioned at the R&D facilities of thyssenkrupp’s cement technologies division Ever since, it has been in operation continuously with numerous tests from CEM I, CEM II/A and B cements, to activated clay/LC 3 products, in separate and in cogrindingthe next level in cement grinding? thyssenkrupp Polysius

Mini Cement Plant, Small Cement Plant 501000TPH EPC Cement Plant

Why a mini cement plant? Mini cement plant is a new cement plant, also known as a small cement plant, which refers to a cement plant with a clinker capacity of 50500tpd Recently, mini cement plant becomes hotter and hotter, what are the advantages of the mini cement plant compared with large or mediumsized cement plants?Cement plants with a clinker capacity below 700tpd can be called mini cement plants or small cement plants Mini cement plants are very popular among small and mediumscale cement manufacturing enterprises since they do not Mini Cement Plant EPC Cement Line Capacity 70 600 TPD

CCG Plant Loesche

The CCG is a smallscale grinding plant designed to produce different types of cement At its heart LOESCHE's wellproven, stateofthe art LM 242 CS vertical roller mill From the feed hoppers, clinker or slag is conveyed to the mill, with the finished product being separated in a highefficiency classifier and collected in the baghouseIn the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Small Scale Cement Plant Mini Cement Production Line

Small Scale Plants in Cement Industry JSTOR

used in most small scale cement plants The number of small cement plants, almost all of them located in rural areas, has increased from about 200 in '1965 to 2,800 in 1973 Total production from the ssmall plant has during the same period increased from roughly 5 million tons to an estimated 20 million tons So, the average size of theSmall Scale Cement Plant,Mini Cement Plant,Hot Sale Cement Machine, Small Scale Cement Plant,Mini Cement Plant,Hot Sale Cement Machine,Cement Plant,Mini Cement Plant,Cement Machine from Supplier or ManufacturerHenan Mining Machinery Co, LtdSmall Scale Cement Plant,Mini Cement Plant,Hot Sale Cement

Modular Grinding Plant AGICO Cement Machinery

The modular grinding plant is developed for small/medium but growing markets, especially for markets that only limited cement production capacity, but also a highly flexible system capable of producing a whole range of types of cementSmall Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory, Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory,Grinding Plant,Clinker Grinding Plant,Cement Clinker Grinding Plant from Mine Mill Supplier or ManufacturerHenan Fantianliang Machinery& Equipment Co, LtdSmall Scale Cement Clinker Grinding Plant And Packaging Unit In Cement

Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement

Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory $13,32000 / Set $14,80000 1 Set (Min order) 10% OFF Discount ends in : : : Model Number: LM grinding mill Power: 20 $13,32000 + Samples: 20,LM grinding mill $49,99900 /Set, 1 Set (MOQ): Get samples Trade Assurance protects your Alibaba ordersDr Kache: In August 2020, a highly flexible small scale trial plant (100600kg/h) was commissioned at the R&D facilities of thyssenkrupp’s cement technologies division Ever since, it has been in operation continuously with numerous tests from CEM I, CEM II/A and B cements, to activated clay/LC 3 products, in separate and in cogrindingthe next level in cement grinding? thyssenkrupp Polysius