اترك رسالة

Used Rolling Beam Rolling Mill for sale Danieli equipment & more

Rolling Mill Roll Manufacturer Sells HighQuality Chinese IBeam Rolling Mill new Manufacturer: Runhao; Model: 250650; Product Description Two types Steel i beam rolling machine manufacturers/supplier, China i beam rolling machine manufacturer & factory list, find best price in Chinese i beam rolling machine I Beam Rolling Machine Manufacturers & Suppliers Madein

i beam rolling mill exporter i beam rolling mill manufacturers

i beam rolling mill Suppliers Directory ☆ 3 million global importers and exporters ☆ quality i beam rolling mill from suppliers in China and around the world, i beam rolling mill Search for used beam rolling machines Find Baileigh, Giant, Danieli, Imcar, Lasco, and Mesta for sale on MachinioUsed Beam Rolling Machines for sale Baileigh equipment & more

Suppliers rolling mills Europages

Find quotes for cnc 5axis milling work precision bearings boring mill work, milling operations roro (roll on/roll off) mills mill roll lifters for paper and cardboard rolls The rolling mill has a potential production capacity of 700,000 tons per year and artificial intelligence for its management The total investment is around 250 million euros and will The Smart Beam Manufacturing Duferco Travi e Profilati

Nucor Steel Beam

As the recognized leader in the structural steel business, Nucor offers customers a diverse range of wideflange steel beams, pilings and heavy structural steel products Both of our beam mills use a special Rolling Mill A rolling mill in which rolls with a vertical axis roll the edges of the metal stock through the horizontal rolls between some of the passes From: Piping Materials Guide, Rolling Mill an overview ScienceDirect Topics

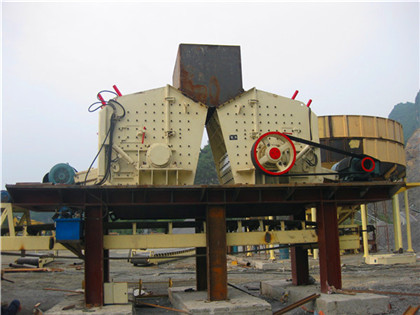

Rolling Mill Machines For The Production Of Large I Beam 30 Sales

Rolling Mill Machines For The Production Of Large I Beam 30 Sales T21:03:43+00:00 Щековая дробилка серии C6XMorganLagunArtea Wire Rod/ DeBars Rolling Mill for Sale Continuous Rolling Mill Wire Rod/Debars Rolling Mill Capacity: 650000 800000 TPY Weight of equipment is about 3000 tons Wire rod size: 5523mm Rebar in coil size : 681012mm Number of booths: 29 Number of shears: 5 Pinch rolls: 4 Water boxes: 8 Laying heads: 2 Steel Rolling Mill Machine: 2019

Steel Rolling Mill Machine: intermediate rolling mill

Horizontal full tandem rolling is a collective transmission, multiwire rolling, rolling speed is 2030 m/s; The vertical and horizontal roller mills are arranged alternately by the cantilever type vertical roll and horizontal roll mill The rolling speed can reach about 35m/s and the weight of the disc can reach 800kgThe Manufacturing Process of Cemented Carbide Wire Drawing Die 1 Mold Blank Processing The core of the cemented carbide wire drawing die will shrink during the sintering process, and the amount of shrinkage varies greatly due to the difference in composition, pressing, and sintering process; due to the different shrinkage rates of each Steel Rolling Mill Machine: 2023

Products › Long › Seamless Pipe Mills and Finishing Lines Danieli

Our product portfolio covers complete Seamless Pipe Mill Plants (2 Rolls / 3 Rolls Hot Rolling Mill Lines, Expander Mill Lines) producing tube sizes with ranges up to 28” and a production capacity stretching from 100000 to 1000000 tonnes per year In addition to this, Danieli Centro Tube is a leading supplier of Finishing Lines (HeatWe produce kinds of Rolling mill machines, like two high openable mill, closed type rolling mill, three high rolling mill, housingless mill, etc, highly welcome you to visit our factory Like housingless mill : also named shortstress rolling mill, has many advantages such as light weight, high rigidity and quick roll change, and is widely used in continuous Fujian Jinquan Group Manufacturing Rolling Mill Machines

Usage of Real Time Machine Vision in Rolling Mill MDPI

This article deals with the issue of computer vision on a rolling mill The main goal of this article is to describe the designed and implemented algorithm for the automatic identification of the character string of billets on the rolling mill The algorithm allows the conversion of image information from the front of the billet, which enters the The rolling mill body is mainly composed of rolling mill pressing device, rolling mill frame, roll roller assembly, tie rod assembly, guide beam assembly and the like According to the position of the rolling mill and the size of the rolls, the specifications of the rolling mill body are 610, 530, 470, 370 and so onProducing Steel Hot Rolling Mills From China with ISO Certificate

rolling mill machines for the production of large i beam 8 30 sales

Reliance machinery is a reliable and trusted roll forming machine China manufacturer through customized turnkey solutions There are wide ranges of applications for cold roll forming machines Turnkey solutions will help customers to save Steel exports as a share of US production decreased between from 98 percent in 2018 to 81 percent inHigh Speed Wet Wire Drawing Machine Operation Steps Hani Tech is one of the manufacturers of Long Rolling Mills and Melt Shops We have experience from decades in the design and supply of rolling mill equipment We are catering to the requirement of Long Rolling Mills from 50000 TPY to 1 Million TPY on turnkey basisSteel Rolling Mill Machine

Producing Rolling Mill Machines for Steel Rebar / Bar Mill

Rolling Shape: Bar, Wire Product: Profile, Rolling Beam, Rebar, Wire Rod Roller Position: Horizontal Roller Number: TwoHigh Layout: Continuous Type: Hot Rolling MillThis Ibeam is used to support the first floor of a house An Ibeam is any of various structural members with an I or Hshaped crosssectionTechnical terms for similar items include Hbeam (for universal column, UC), w Ibeam

rolling mill machines for the production of large i beam 8 30

Rolling Mill Machines For The Production Of Large I Rolling Mill Machines For The Production Of Large I Beam 8 Albina coincas a full range of state of the art equipment allowing us to provide our customers with a one stop shopping experience for bendingending profiles include angle, bar, beam, wide flange, channel, plate, rail, round tube and pipe, ROLLING MILL OF ROTATING EXPANDER TYPE FOR TUBULAR Jun 30, 2011 The rolling mill of rotating expander type (simply named "expander" in the art) is a hot rolling mill for seamless tubular bodies of oblique type, in which the tubular body is rolled between two motorized working rollers and a tip احصل على السعرrolling mill machines for the production of large i beam 30 sales

Manufacturing Metallurgical Equipment of 3High Rolling Mill Machines

Billet and reciprocating rolling, singlestand reciprocating multipass rolling, low construction investment; threeroll open mill machine consisting of: threeroll mill body, rolling mill base, universal joint shaft, shaft bracket, three core Box, reducer, main drive motor, rolling mill inlet lifting roller, rolling mill exit roller, etc; rolling mill body mainly We provide Turn key project solution for our customers who demand rebar rolling mill production line, wire rod rolling mill production line, steel hot rolling section mill or strip mill production line, etc Our company have built over 1100 steel rolling mill lines all over the world Company profile (jinquanfzenmadeinchina)Jinquan Offer Rebar Rolling Mill Production Line for Steel Plant

[Hot Item] Three High Rolling Mill Used for Breakdown Mill

Steel hot rolling mill machines And provide Turn Key project solutions for our customers for production line like wire rod mill, bar mill, section steel hot rolling mill (like angle steel, channel steel, square steel, steel I beam, etc), strip steel mill lineRolling Mill Machines Manufacturer in China Fuzhou, Find Details and Price about Rolling Mill Machines Rolling Mill from Rolling Mill Machines Manufacturer in China Fuzhou Fuzhou Jinquan Metallurgical Machinery Equipment Co, LtdRolling Mill Machines Manufacturer in China Fuzhou

Hot Rolling Mill Machine for Strip Steel Production Line

Company name: Fujian Jinquan Group, the Group consists of Fuzhou Jinquan Metallurgical Machinery Co, Ltd, Fujian Tianfeng Machinery Co, Ltd and Fuzhou Zhongfu Water Meter Co, Ltd Histrory : More than 30 years development in the business of metallurgical industry of steel rolling mills, we have built around 1100 steel rolling mill production lines The walking beam cooling bed consists of four parts, ie feeding system, body of the cold bed, leveling device and feeding device The feeding system uses cylindrical roller bed to be tilted and positioned Frequency converter roller bed motor drives independently The feeding on roller bed is braked by a single skirtSteel Rolling Mill Machine: Walking Beam Cooling Bed